HOW IT WORKS

For printed labels we offer a wide range of sizes and dimensions without Die Cutting fees, unless it is a special shape, say, like an alien head logo, or an elephant for example. Any special shape outside of standard dimension squares, circles and rectangles would require a custom die cutting fee.

Die cut fees are a one-time fee and generally run in the range of $150-$300 depending on the size and dimensions of the die cut being made. We offer so many sizes of circle, square, rectangle labels that 99% of the time we do not charge a die cut fee when using these standard shapes.

When it comes to printing labels for products, you will notice that most of the time the label dimensions are a circle, square or rectangle shape. Usually when a client has a specific product they need a label for they will come to us with a specific dimension for the label, but we often will offer the “Closest to” size, which is usually a perfect fit and within millimeters of the original size they wanted.

Usually when you purchase a product from a manufacturer or vendor, they will give you a label size that you should adhere to. We use this information to find you the closest size you can use without having a custom die cut made and without sacrificing the look of the label or the final product. This is how we avoid expensive die cut fees, therefore saving you much money.

We help you find the proper “Closest To” label size by sending you a sample label cut line that you can print out and cut out to test on your product. Simply cut out the shape we send you, wrap the test shape around your product to make sure it fits good.

We offer 2 types of lamination, Glossy Lamination and Matte Lamination. We can print without lamination but we do not recommend that because without the lamination it is possible that the inks will smudge or smear if they come into contact with moisture, oils, or water. The lamination protects the inks on the labels from any foreign elements or moisture that may be encountered during product filling, packaging and shipping.

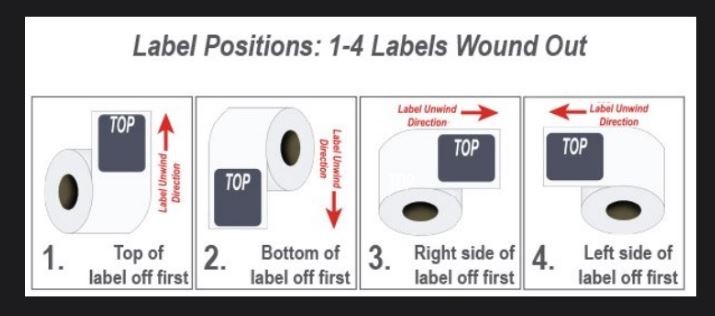

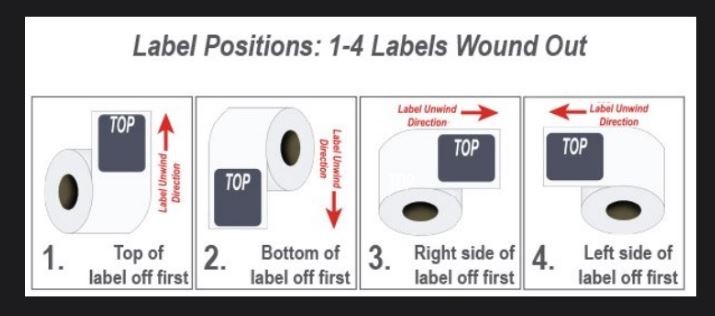

If you are printing labels with us and would like us to send them to your product manufacturer or co-packer for application with their machines, we will need you to specify the label roll direction configuration so we can make sure your labels are wound properly and will unwind properly for the label application process. The label roll configuration can be obtained by simply asking your product manufacturer or co-packer what roll direction they require. The label roll direction is a standardized process that all printers, co-packers and manufacturers use when applying labels by machine. The roll direction configurations are as follows;

If you are hand applying for labels, your label rolls will be configured in a #3 right side of label off first configuration by default.